Akropars layout plans and engineering facility plans for laundry projects in hotels, hospitals, factories, etc. are drawn using expert design engineers with extensive experience in this field to prevent possible damages and depreciation that may occur in the future.

Without a doubt, having technical information before installing laundry machines will prevent subsequent financial losses.

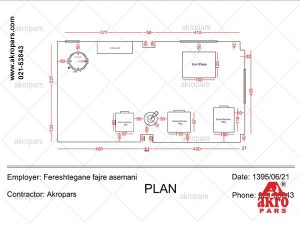

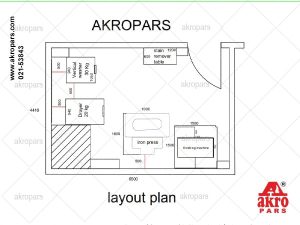

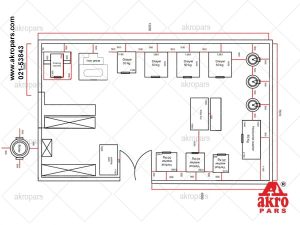

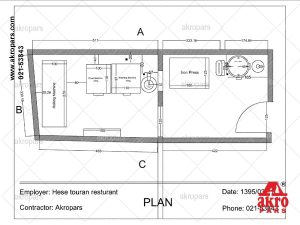

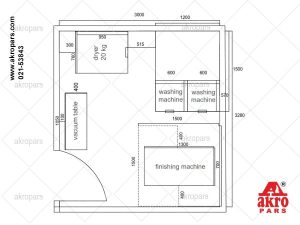

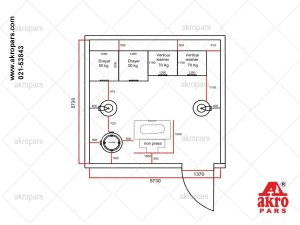

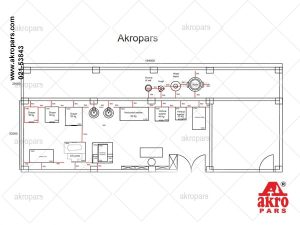

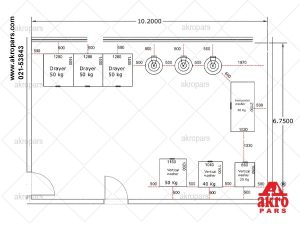

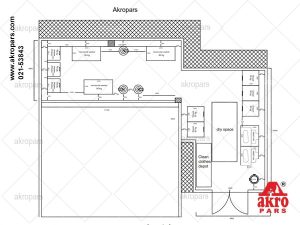

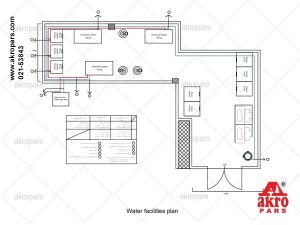

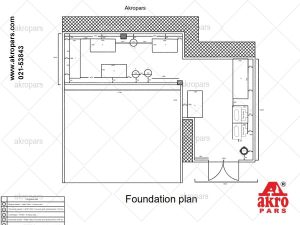

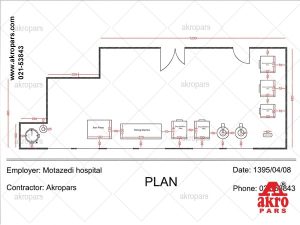

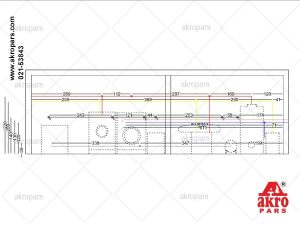

Sample layout map of Akropars for some completed projects

You should also consider the size of the laundry equipment. Often, the wrong equipment is purchased that either won’t fit through the laundry room door or won’t fit through the hallways leading to it.

Laundry conditions requirements

In this regard, several things should be considered:

- Required space according to the number of rooms, halls after calculating the machines

- Installing a chute from the top floor to save manpower

- Enough light to see all kinds of stains on clothes and laundry items

- The facility map is provided according to the machinery.

- Ventilator to remove contaminated air from the workshop

- Sewer outlet, overlooking the main sewer to direct washing wastewater

- Close to the elevator for transporting hotel laundry supplies to the relevant areas.

- Designating a large room as the Lenin Room, where the laundry’s work would be stored.

- Having a high ceiling

- Separation of clean and dirty areas

- Arrangement of washing machines in order of ironing

- And a series of points that should be considered specifically for each project.

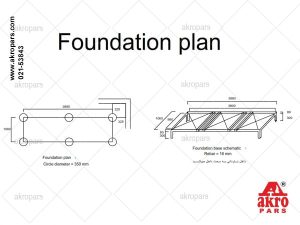

What characteristics should the foundation of the devices have?

In the Akropars layout plan, one of the items is the foundation, for which the relevant plan must be provided for the devices that are required.

On the constructed platform, in the middle of which the calculated chassis is placed (sand_cement_gravel), concrete is poured and at certain distances, the chassis is restrained from several places, especially the dimensions of the reservoirs, due to vibration and runaway (centrifugal movement).

The concrete platform must be such that the flat surface of the chassis can be touched, and the height of the platform to the chassis surface must be calculated so that after installing the ceramic, the entire chassis surface is available for welding the gutter under the machinery.

Then, considering the length of the machines and their layout, the distance between the machines and the back wall should be a maximum of one meter and the distance between the machines should be a maximum of 50 centimeters.

It is better to calculate the required machinery before concreting and determine the locations of sewage, electricity, cold and hot water, and floor washing in the foundation plan. Then, during implementation, the foundation of the laundry room is built on the ground with insulation and safety, and then the flooring is laid, which will give a special beauty to the machinery and the area of the room.

Laundry facilities must be separate and on-site.

For greater safety, prevention of incidents and acceleration of their containment, it is emphasized that the facilities near the laundry door and access, the cold and hot water inlet valve, steam (if branched from the facility’s boiler), and gas should be installed in compliance with the safety of the main electrical panel of the machinery. Upon arrival, open the cold, hot, steam, and gas valves and the power switch. At the end of the daily activity, similarly, close the valves and turn off the main electrical switch of the panel, so that no accidents occur in the laundry at night. If an accident occurs during daily work, all currents should be immediately cut off and the activity should be resumed after the fault is fixed.

(dry cleaning room) Dry cleaning room on the Akropars layout map

Another room and location are designated for installing a washing machine and stain removal machine, where all stain removal and washing steps with perchlorate are performed using the washing machine.

Perchlorethylene may cause allergies. They prefer that the relevant machine and the equipment used be installed and maintained in a special room. When the clothes are separated, those related to stain removal with a stain removal machine and dry cleaning are transferred to that area. After completing the relevant tasks and preparing for ironing, they are transported to the pressing area and made available to the press workers for ironing.

In general, laundry layout and architecture are mainly carried out by companies that handle projects in a specialized and complete manner. We can fully assist you in designing the layout plan and facilities for your project.

The devices and equipment that must be installed or prepared in the laundry area include:

- Washing machine (industrial washing machine)

- Dry cleaning and bleaching (dry cleaning machine)

- (centrifugal machine)

- (dryer machine)

- (ironing rolling machine)

- (ironing press machine)

- (Iron Mannequins)

- spotting table

- (steam boiler)

- Shelves

- Special clothes racks for washed and ironed clothes

- Rack with baskets for dirty clothes